TAS 組合式選粉機(jī)

結(jié)構(gòu)特點(diǎn)

TAS 組合式選粉機(jī)為我公司近年開發(fā)并推廣的產(chǎn)品,與輥壓機(jī)配合使用,可用于新建或改造的生料磨、水泥磨、礦渣(鋼渣)磨等系統(tǒng)。該機(jī)型將高效動(dòng)態(tài)選粉機(jī)與 V 型靜態(tài)選粉機(jī)組合為一體,結(jié)構(gòu)緊湊、運(yùn)行空氣阻力低,能有效降低系統(tǒng)電耗。

●動(dòng)靜態(tài)一體設(shè)計(jì),降低土建高度和沿程阻力損失;

Combination of the static and dynamic separator – lower total height and lower pressure drop.

●靜態(tài)部分更扁平、動(dòng)態(tài)部分出風(fēng)口擴(kuò)容、整機(jī) CFD 流場(chǎng)優(yōu)化,局部阻力損失更低;

Static separator is more flat, enlarged air outlet of dynamic separator, Optimized flow field with CFD – lower pressure drop.

●組合式密封、后傾轉(zhuǎn)子葉片、可調(diào)導(dǎo)流葉片,調(diào)節(jié)更靈活、選粉效率高;

Combined sealing, back inclined rotor blade, adjustable guide vane - high separating efficiency.

●動(dòng)態(tài)部分粗粉返回靜態(tài)部分并設(shè)計(jì)調(diào)節(jié)裝置,控制內(nèi)循環(huán)、提高二次分選能力;

Between danamic and static separator, adjustment device is equipped to control the internal circulation, thus improve the secondary

sorting ability.

●設(shè)備阻力:~3500Pa,比傳統(tǒng)動(dòng)態(tài)選粉機(jī)加 V 型選粉機(jī)低 500~700Pa,電耗更低;

Equipment pressure drop:~3500Pa, 500~700Pa less than original dynamic separator and V- separator.

●選粉效率:>90%,比傳統(tǒng)動(dòng)態(tài)選粉機(jī)加 V 型選粉機(jī)高 5-10%,產(chǎn)量更高;

Separating efficiency>90%, 5~10% more than original dynamic separator and V- separator and larger production capacity.

●建造成本:扁平化設(shè)計(jì),土建高度比傳統(tǒng)動(dòng)態(tài)選粉機(jī)加 V 型選粉機(jī)低 5~8m,建造成本更低。

Construction cost: Compact design, the height of the system is 5~8m lower than the traditional dynamic separator and V- separator

design, thus lower the construction cost.

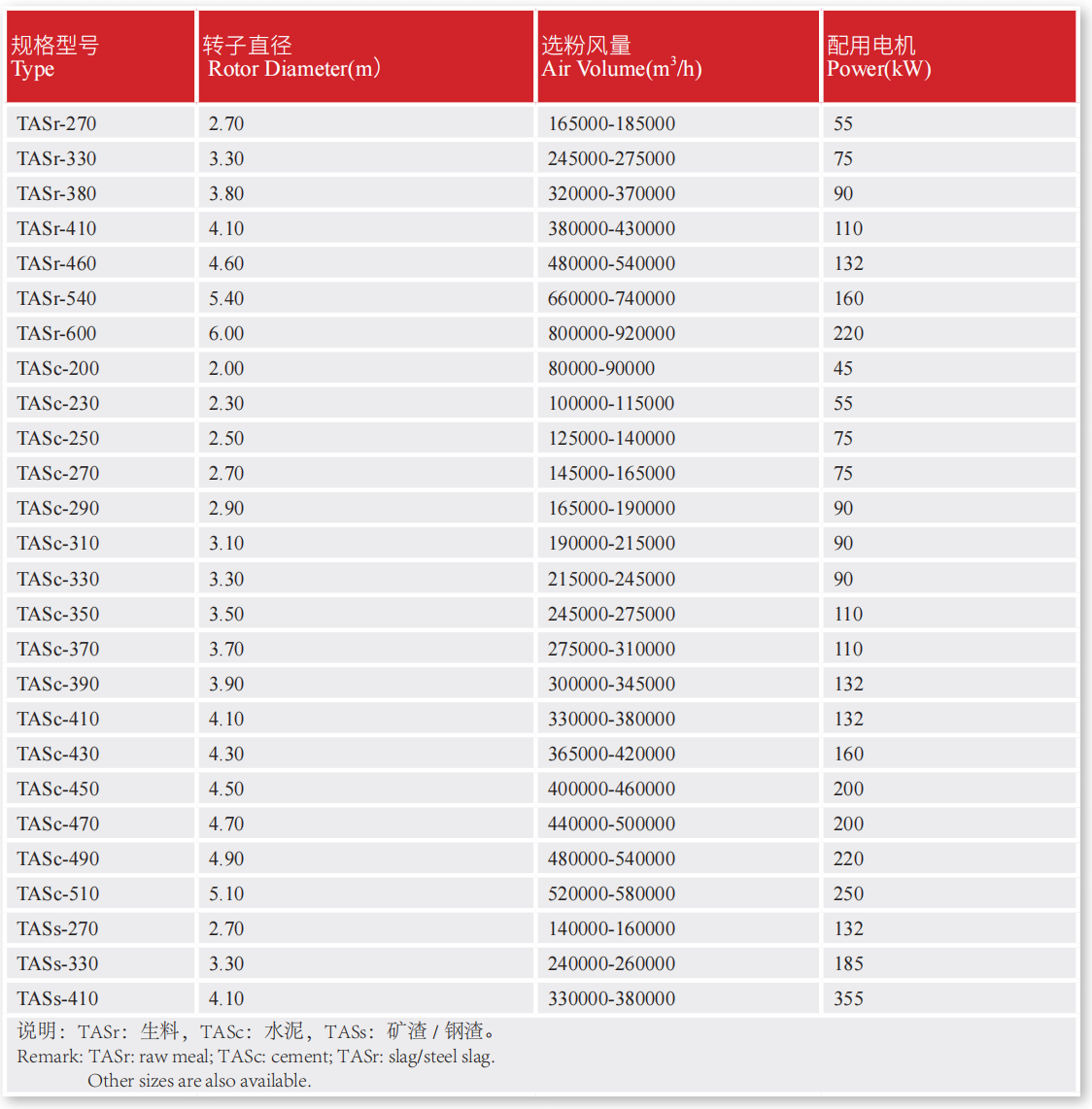

組合選粉機(jī)型號(hào)及參數(shù)